Technical Aspects

Experience how easy and efficient programming is with our technology. Our development platforms are specifically designed to enable intuitive and powerful control of ISELED® LEDs.

Arduino IDE

The open-source Arduino software (IDE) allows you to quickly and easily upload code to the board. This is a real advantage for our customers, as the platform is particularly intuitive, flexible, and ready to use immediately.

FastLED – Animation library

If you want it to look particularly beautiful, you can easily control your ISELED® lights with the FastLED animation library by simply replacing the FastLED commands with FastISELED.

Control ILaS® from the PLC

– fast, secure, scalable

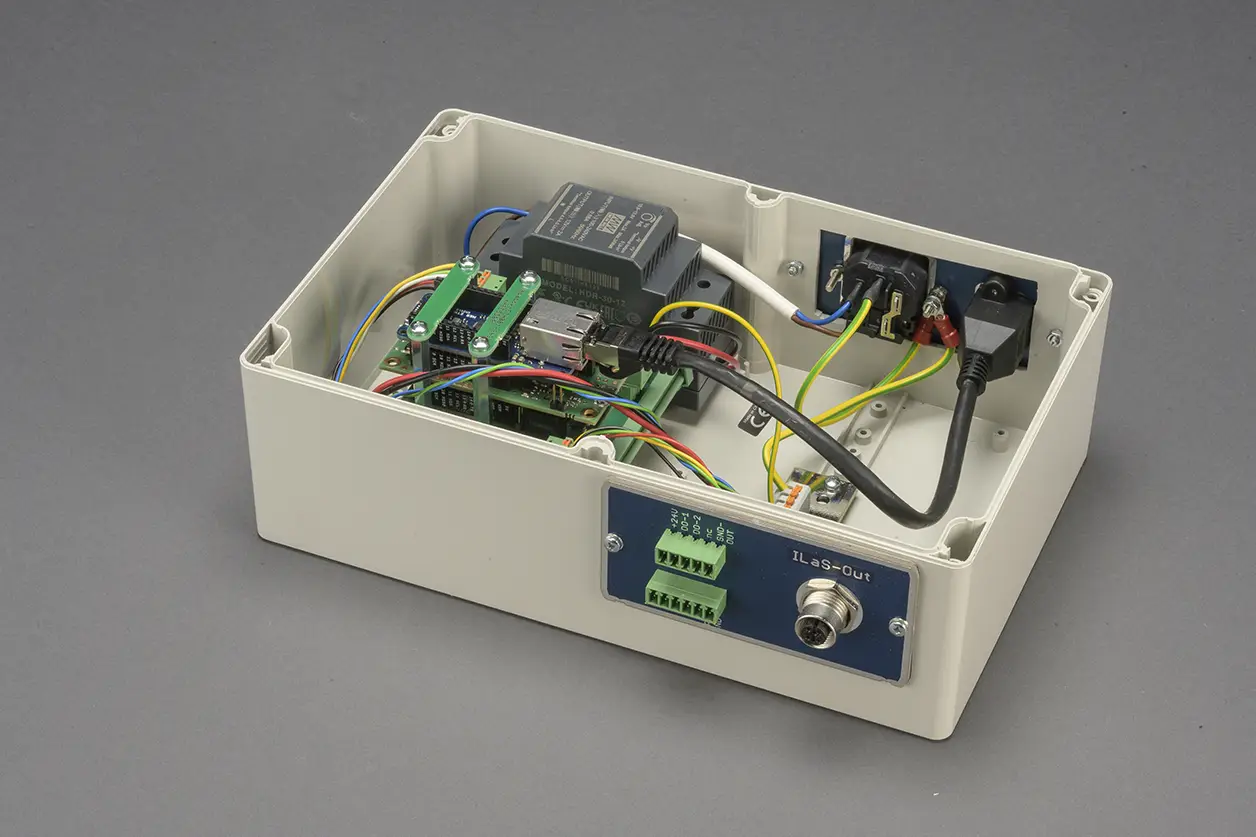

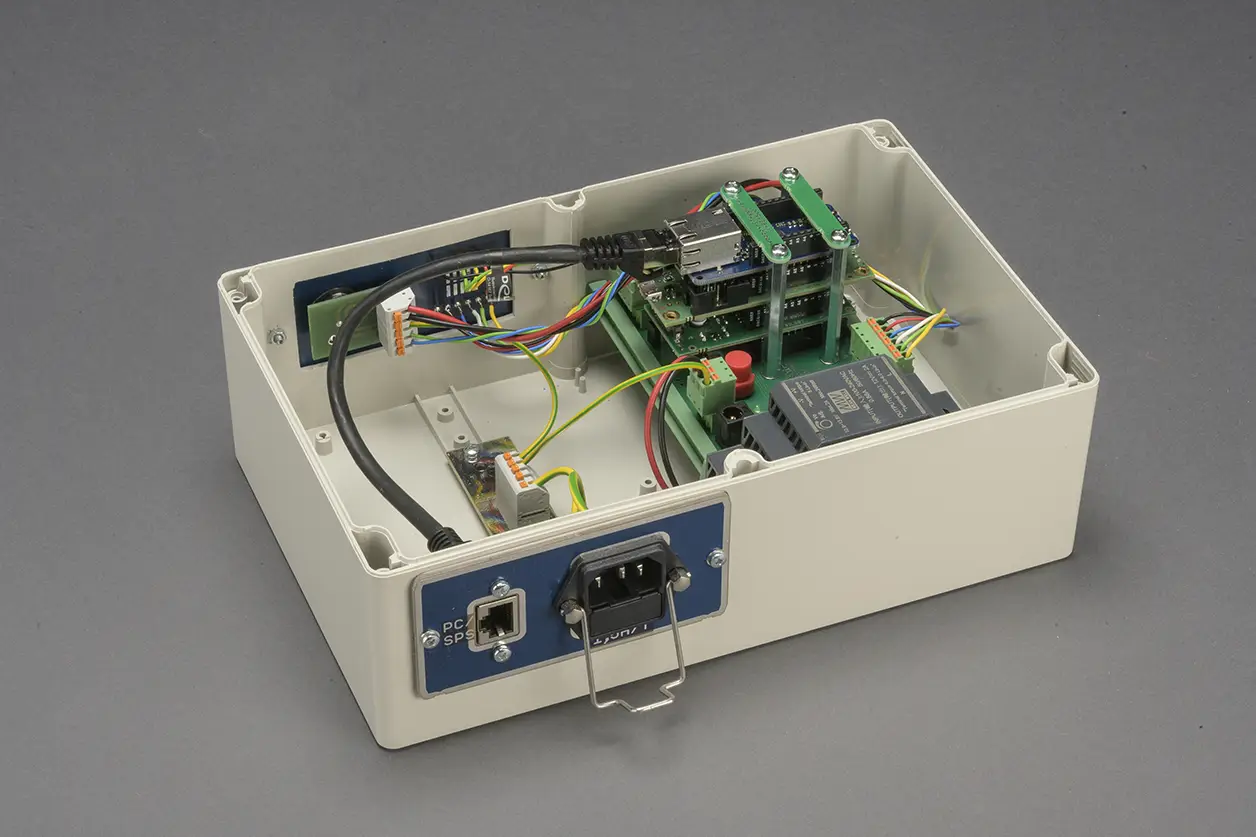

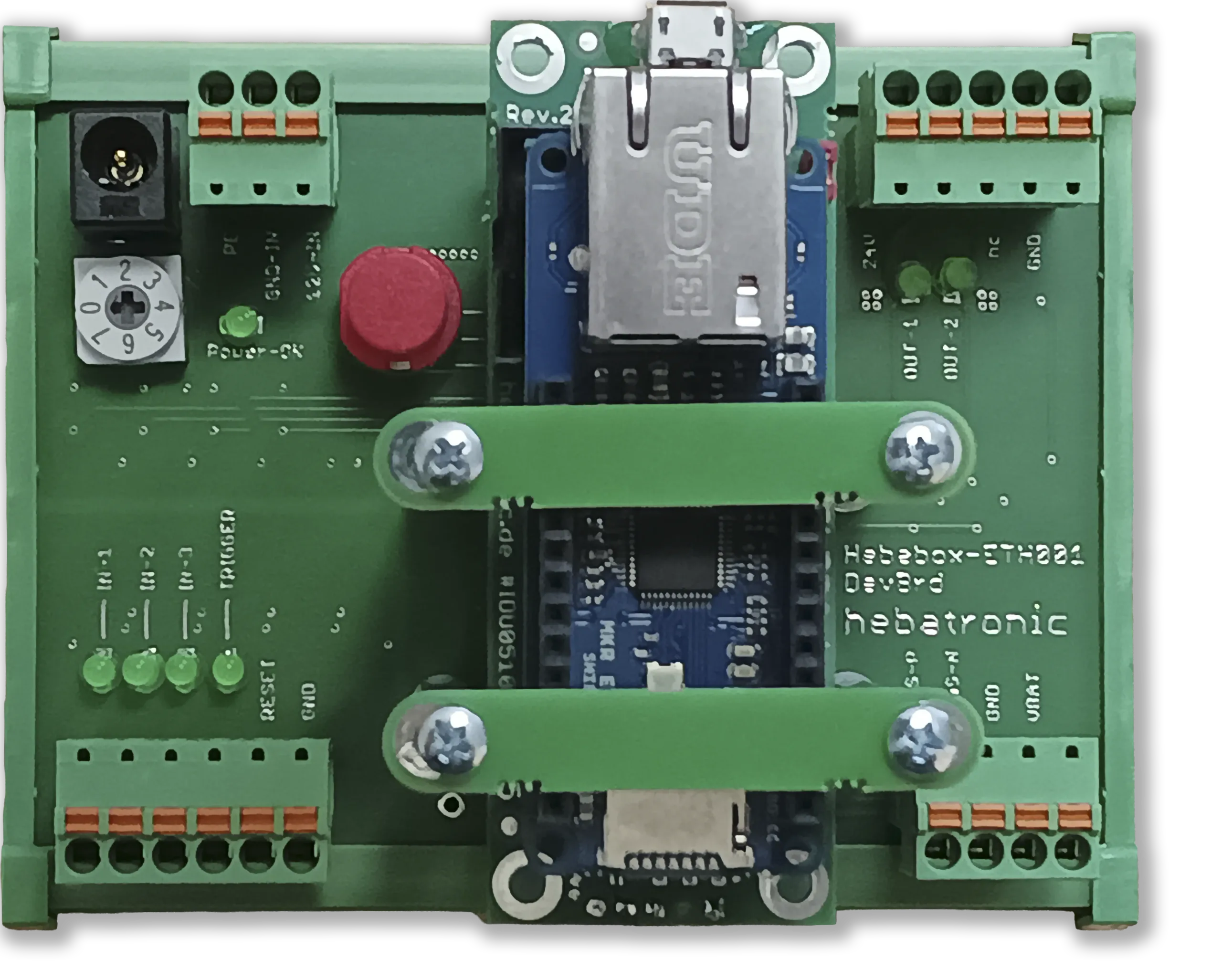

The Hebabox makes setpoints and status information of your ILaS® nodes directly available in the PLC via Modbus TCP. This allows you to integrate EOL test benches and automation systems without extensive adjustments.

Why Hebabox?

01/04

How the Hebabox works

- 1Select command & write parameters – via Modbus register.

- 2Execute – the Hebabox (ISELED®uino + Hebatronic library) communicates with the ILaS® nodes.

- 3Read result – status and data are returned in a structured way via registers.

If desired, we adapt the command set and register layout to your project-specific needs.

02/04

Integration & compatibility

Optional: We implement use-case-specific embedded extensions (e.g., performance optimization) as needed.

03/04

Technical Change Note – Bootloader (SAMD21)

For the Hebabox and Hebastack, a modified version of the Arduino SAMD21 bootloader is used.

The modification is deliberately minimal and affects only one file: bootloaders/zero/main.c

In this file, an additional security routine has been integrated: security_bit_check_and_set()

Purpose of this modification:

Checks during boot whether the SAMD21 Security Bit (SSB) is already set

Automatically sets the SSB if it is not yet activated

Ensures that the microcontroller cannot be read out without a full chip erase

Provides reliable firmware protection for the Hebabox / Hebastack

The application firmware itself is not affected by this modification and remains fully proprietary.

04/04

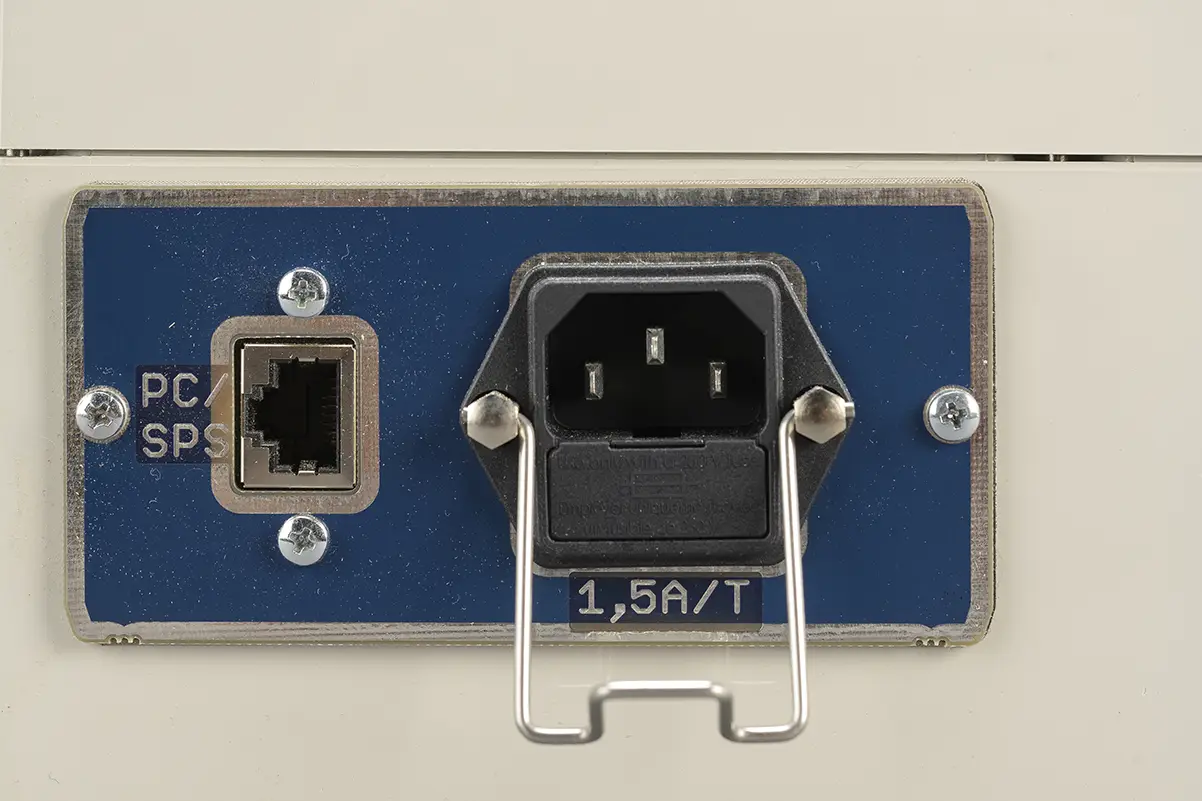

How do you connect the Hebabox to a PLC?

PLC integration

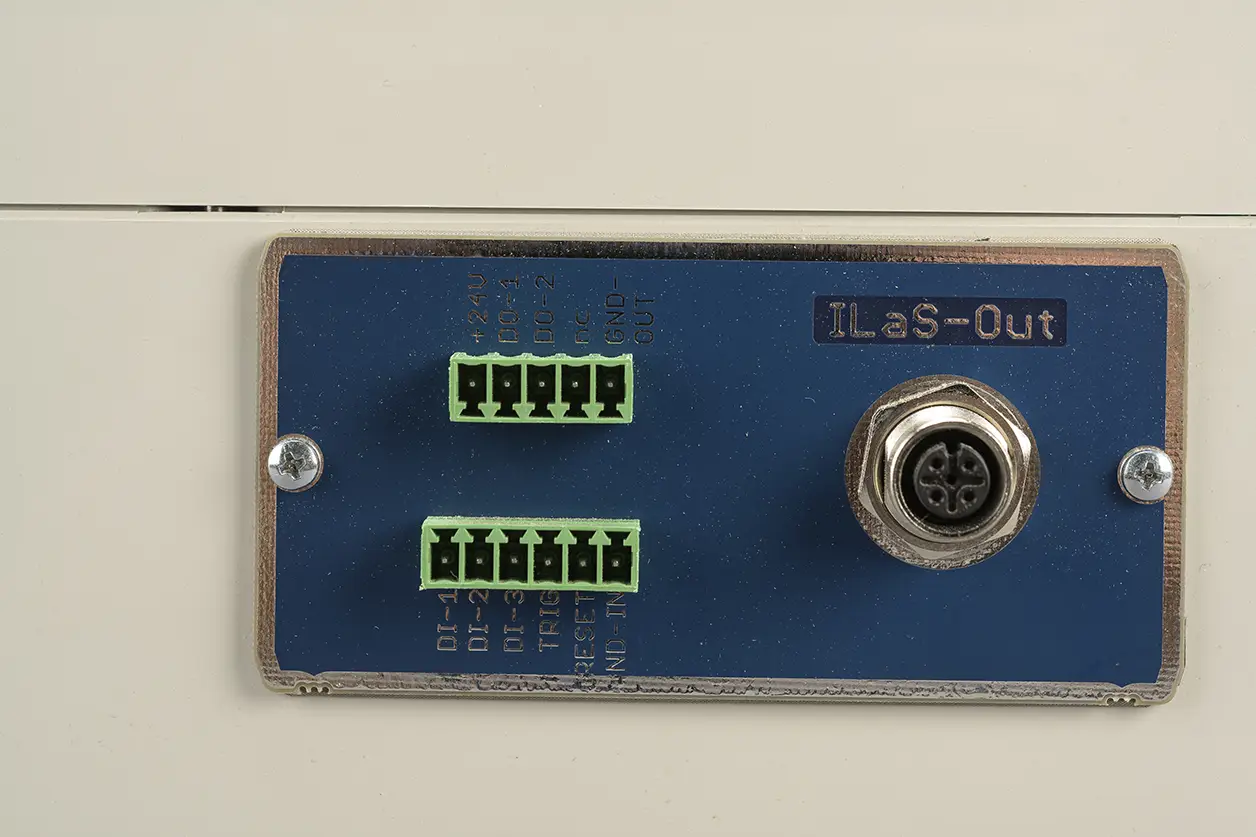

ILaS® directly at the PLC — ready to use: either via Ethernet/Modbus TCP or via 24 V I/Os. Seamlessly integrable into existing lines; trigger/reset/status optionally via register access or I/O. The ILaS® bus is controlled directly by the Hebabox. Scalable, robust – ideal for EOL testing, rework, and series production.

01/03

Digital I/Os for test systems

Thanks to integrated digital inputs and outputs, assemblies and test sequences can be controlled directly. This enables reliable control and monitoring of test functions in real time.

02/03

Scalable gateway solution

The Hebabox is based on our proven platform components – ISELED®uino and ILaS® shield as well as an Arduino® MKR Ethernet shield. It is available as a desktop device, DIN rail module, or rework box; all variants can be assembled modularly and expanded as needed – ideal for use in industrial testing and production lines.

03/03

Everything you need to know about our Hebabox

Here you will find answers to the most common questions about our Hebabox. If you need further information, visit our Help Center or contact us directly.

For the complete package – enhance your solution

with our additional products

New series

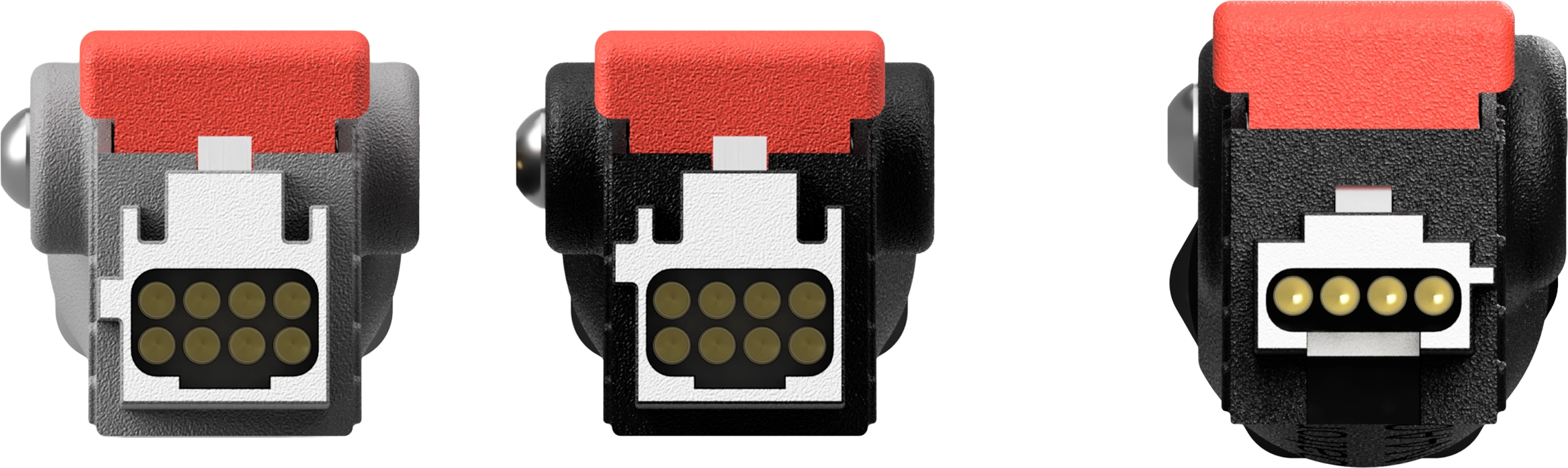

Hebatronic 3D Connector Series

Precise, robust, and customizable connectors for prototypes, validation, and EoL testing. Hebatronic’s 3D connectors combine mechanical stability with maximum flexibility. They are manufactured using SLS or MJF processes and are optimized for prototypes, test benches, EoL testers, and small series—ideal for applications such as ISELED®, ILaS®, or LED modules.

New

Hebastack

The Hebastack is the compact board-stack solution for ILaS® and ISELED® systems. Without housing, without power supply, and even more compact than the Hebabox, it is specifically designed for direct integration into control cabinets and EOL test benches. It provides full gateway functionality with Ethernet (Modbus TCP) and digital I/Os – extremely space-saving, flexible, and ideal for automated quality assurance.

Ready to revolutionize

your lighting systems?